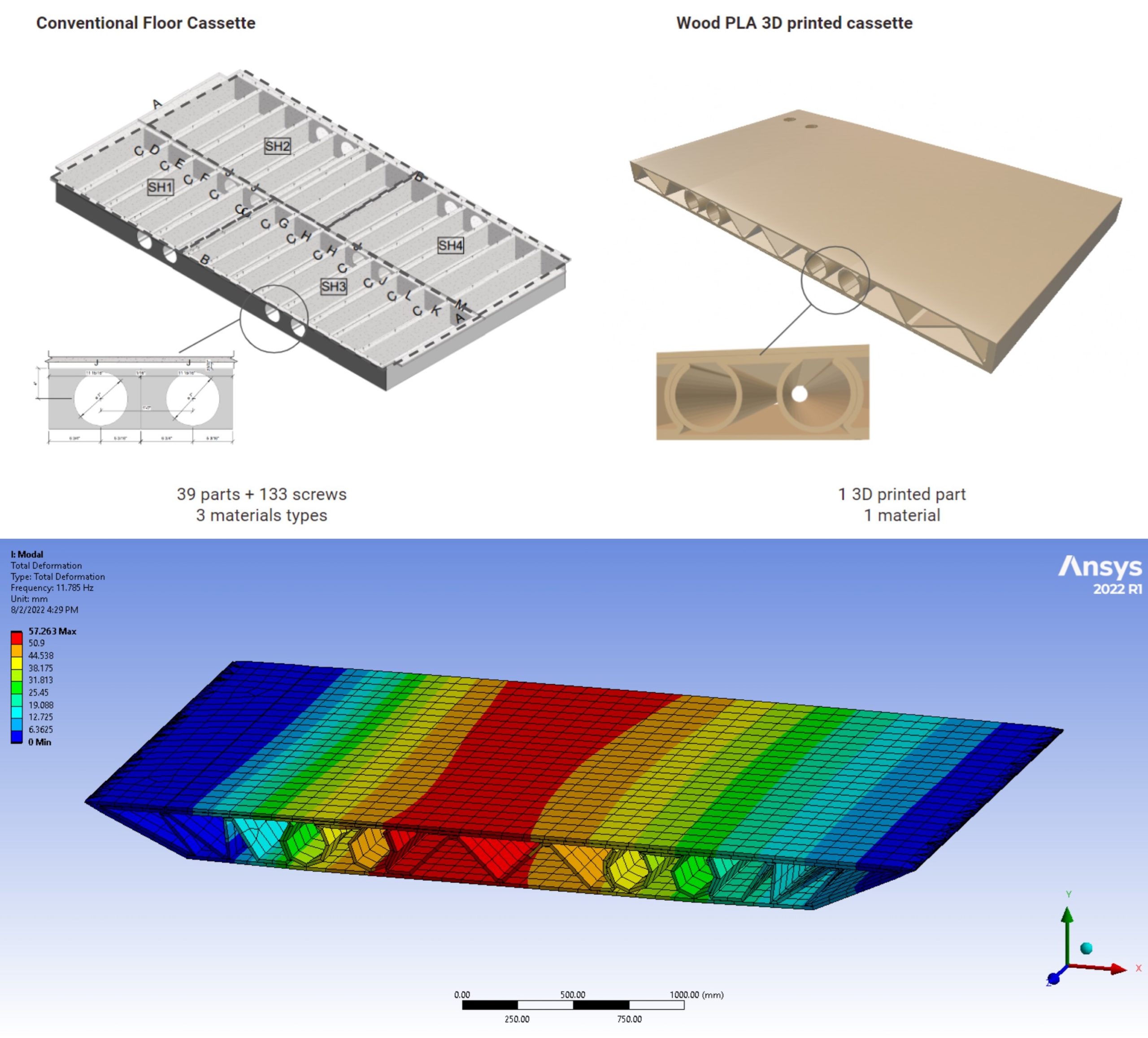

Researchers on the College of Maine have launched photographs of the 3D-printed, natural-material ground cassette they are saying is robust sufficient to exchange steel-and-concrete flooring in multi-storey buildings.

The college labored with the US Division of Power’s Oak Ridge Nationwide Laboratory (ORNL) to develop the “SM2ART Nfloor cassette”.

It’s comprised of a mixture of polylactic acid (PLA) – a biodegradable thermoplastic derived from corn residue – and wooden flour from lumber-processing waste.

“The PLA and wooden flour mix is a wonderful materials for producing recyclable, large-format additively manufactured elements,” stated Scott Tomlinson, structural engineer with the College of Maine’s Superior Constructions and Composites Middle (ASCC).

“This single-piece ground meeting is stiffer and supplies an improved strolling expertise when in comparison with the steel-concrete meeting it replaces,” he added.

ORNL researcher Katie Copenhaver stated: “By utilising bio-based, large-scale 3D printing, we changed an meeting comprised of 31 elements and three supplies with a single-material ground panel that’s ecologically pleasant and with the identical power as conventional metal ground fabrication.”

Labour-saving

The printer laid down layers for the geometrically-shaped cassette in about 30 hours, which researchers stated represented a labour saving of about 33% in comparison with constructing a standard ground.

It was programmed to go away openings for electrical, plumbing, and air flow providers.

Researchers stated an enormous a part of the price of conventional ground building comes from employees slicing such openings retrospectively.

“3D printing can save money and time by printing the ground cassette with cutouts designed into the completed product,” stated Copenhaver. “The one human labor includes putting in acoustic pores and skin for sound proofing and the resident’s desired ground masking.”

The cassette is absolutely recyclable, in accordance with the researchers.

SHoP Architects’ thought

The concept for the mission got here from New York Metropolis-based SHoP Architects.

“They requested if we may mass-produce ground panels extra effectively with greener supplies and additive manufacturing,” stated Copenhaver.

“Determining one thing new, contemplating totally different variables, is a trademark of ORNL. Via experimentation, we labored out the appropriate speeds and made the tweaks wanted to reliably produce a completed half with the specified completed look and high quality.”

Analysis strikes now to flame retardants, insulation, and higher manufacturing strategies.

UMaine’s Scott Tomlinson stated the know-how “holds a variety of promise for the way forward for sustainable buildings”.

- Subscribe right here to get tales about building around the globe in your inbox 3 times every week

Extra on different supplies:

- Bamboo agency wins €250,000 bio-material prize

- Rotterdam to get demountable timber social housing block

- European corporations unveil concrete-timber hybrid partitions

The submit See the printed ground cassette researchers say may exchange concrete, metal appeared first on World Building Assessment.