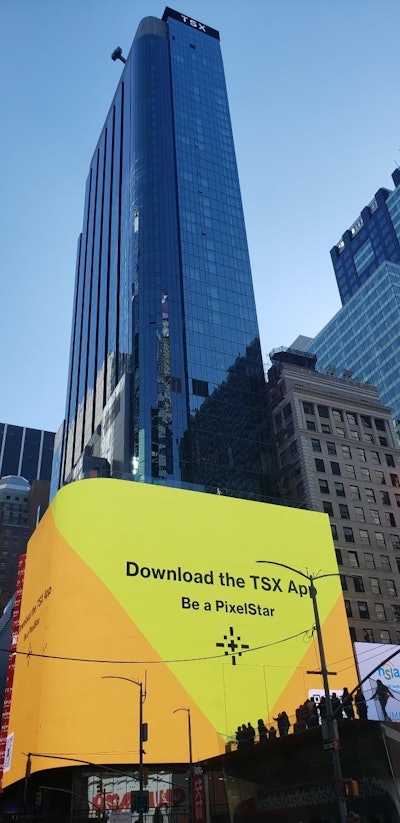

In Instances Sq., buildings should be bigger than life. Twenty-two p.c of each New York vacationer greenback is spent in Instances Sq., and it receives 400,000 guests per day, in line with the TSX Broadway web site. The TSX property—a 550,000-sq.-ft. “leisure ecosystem” containing a mixture of retail, live performance house, and 661-room resort—was accomplished in early 2024.

The undertaking redeveloped an current Eighties tower constructed over the circa-1910 Palace Theater. The theater inside was landmarked, however since this meant solely the within of the constructing wanted to be preserved, the design group determined to boost the construction and incorporate it right into a portion of the brand new constructing that’s 30 ft. above avenue degree. Doing so freed up ground-level actual property in Instances Sq.’s highly-sought-after retail atmosphere. One other problem for the constructing group was that 25% of the Eighties tower wanted to be retained with a view to keep a zoning exemption. To satisfy this objective, the structural components of the lower-story flooring slabs had been retained, complicating demolition and excavation actions. Chopping-edge concrete development methods supplied the energy and stiffness obligatory for the structural techniques and helped accomplish the location’s transformation from a dated, limited-use theater house right into a dynamic retail and leisure hub.

TSX Redevelopment Challenge Value: $2.6 billion

Structural Options

A post-tensioned system was used to switch hundreds from the previous structural system to the brand new one and a concrete ring-beam that was used to elevate the Palace Theater. For below-grade development, a brand new concrete system was created to help the prevailing construction whereas the muse was lowered by 30 ft. to accommodate a brand new subcellar. This technique redirected hundreds to concrete columns supported on newly put in caissons.  The TSX constructing, Instances Sq., New YorkTSX Broadway

The TSX constructing, Instances Sq., New YorkTSX Broadway

Sequencing for the undertaking was crucial. The present resort tower had been constructed round and above the Palace Theater, which occupied the nook of the block. To help the tower, super-columns had been positioned on the theater’s corners and a deep truss system positioned on prime of it. The primary part of development for TSX Broadway, which started in 2018, concerned upward extension of the super-columns, demolition of the prevailing tower from the highest right down to the prevailing degree 16 slab, and basis work.

A post-tensioned girder system was created to de-load the current truss and supply help for the longer term tower. A complete of three post-tensioned concrete girders, every 41 ft. deep, 4.5 ft. large, and 140 ft. lengthy, had been put in in 4 separate vertical pours. Formwork was supported on the prevailing trusses for the primary elevate, which was post-tensioned utilizing 1,700-ton stressing jacks. The girders had been then constructed in 10-ft.-deep increments and had been post-tensioned with every increment. Additional post-tensioning occurred when development progressed to the higher tower flooring. At that time, tendon-stressing was calibrated following the development of every 10-floor tower section. This gave the girders a slight upward camber, controlling stresses and limiting deflection. Actions had been carefully monitored as development progressed, and at completion, the girders exhibited deflection of solely 1 / 4 inch. Thirty-six high-strength tendons, measuring a complete of 210,000 ft., had been tensioned to 2,000 kips every.

The three girders are braced by 16-in.-thick cast-in-place concrete slabs on the twelfth and sixteenth flooring. Current resort tower slabs that had not been demolished had been hung from the brand new post-tensioned super-truss, and the brand new truss additionally helps the raised theater constructing. It’s the longest post-tensioned concrete switch truss for a vertical constructing on the planet.

As soon as the brand new help podium was in place, the previous truss system above the Palace Theater was demolished. At that time, one other of the undertaking’s most difficult duties commenced: a 6-ft.-thick concrete ring beam was poured to behave as a base for the 14-million-lb. masonry theater. The ring beam was put in in segments on the underside of the bottom flooring framing by first pocketing metal posts into the partitions after which changing the brick with concrete in lengths of 30-40 ft. Shoring posts and jacks had been used to elevate the theater. Utilizing the ring beam minimized the chance of cracking the theater’s masonry partitions.

Concrete additionally helped the group obtain the 25% construction retainage requirement. The structural capacities of some current slabs had been elevated by bonding them to structural topping slabs. In one other location, a bolstered concrete slab was epoxy-pinned to an current concrete plate. The ensuing increased load capability allowed for the removing of inside columns. New concrete was additionally used to reinforce the prevailing metal super-columns’ buildings for the reason that enhance within the constructing’s stay and lifeless hundreds meant that every super-column now should help 25 million lbs. From the cellar to the eighth flooring, current columns had been encased in 14,000 psi concrete bolstered with Grade 80 rebar. Above the eighth flooring, columns had been completely constructed of high-strength bolstered concrete.

Early selections on the a part of the development group to make use of concrete as a substitute of metal for the structural system had been primarily based on value as properly as the pliability of concrete to be positioned on the tight city website.

Improvements within the Concrete Combine

Excessive-performance concrete was a requirement for the undertaking. Slag cement, included at 40%, not solely helped obtain excessive efficiency however made the mixes low-carbon. Heidelberg Supplies North America equipped slag cement, in addition to portland cement, to Tec-Crete Transit Combine, who equipped the concrete used within the constructing’s development. Stan Trella, gross sales supervisor at Metro New York/Lengthy Island for Heidelberg Supplies North America famous that the usage of slag cement was useful to not only one) optimize the concrete’s energy however 2) scale back the venue’s environmental impression by decreasing the proportion of odd portland cement (OPC) within the combine.

Each objectives of concrete provider, Tech Crete Transit-mix Corp.

Assuming business averages for the world warming potential (GWP) related to portland cement and slag cement, the TSX Broadway undertaking saved greater than 6.8 million lbs. (3,000 metric tons) of CO2. (Trade averages for portland cement are printed by the Portland Cement Affiliation and, for slag cement, by the Slag Cement Affiliation.)

A 14,000 psi (96.5 MPa) design energy combine accounted for 38% of the concrete positioned on the undertaking. Greater than half (58%) of the concrete positioned had a design energy of no less than 10,000 psi; every had a minimal of 40% slag substitute.

The 580-ft. Tall Tower

The 580-ft.-tall TSX Broadway tower represents a rise in constructing top of 100 ft., permitting for increased floor-to-floor heights in the brand new resort. The broader column spacing on the tower’s decrease ranges (enabled by the rise in slabs’ structural capacities) permits flexibility in leisure areas. One hospitality lounge options the most important terrace in Instances Sq..

A spotlight of the constructing is a cantilevered leisure stage that’s 30 ft. above seventh Avenue. A hinged LED door—a part of the 18,000-square-foot LED display screen that wraps round 9 of the constructing’s decrease tales—opens to disclose the stage; when closed the door is a part of the high-resolution show. Different digital signage is positioned alongside the peak of the tower and at its crown, providing a complete of 51,000 sq. ft. of promoting house.

Challenge value for the TSX Broadway redevelopment was $2.6 billion.