Matt Hedke is director of VDC Options at Southfield, Michigan-based contractor Barton Malow. Opinions are the creator’s personal.

Developments in expertise usually happen after some trial and error, however their success isn’t any accident. Business-changing improvements require cautious planning, a deliberate course of and, most significantly, a dedication to innovation and the empowerment to “fail ahead.”

Empowering staff members to innovate from the highest down is vital to continued development and new concepts, however empowerment with out an organized course of is not only inefficient — it may be pricey, too. We discovered that whereas our individuals constantly pushed the envelope and developed artistic options, a lot of it was taking place in silos, leading to pockets of innovation with none framework to maximise it.

That’s when management initiated a deliberate effort to develop a scalable course of that groups throughout the group might repeat, in the end leading to extra widespread deployment of trials to additional change the sport.

To make sure effectivity in price and time it was vital to first assemble our Innovation staff, which included individuals from totally different roles throughout the group for preliminary evaluate of any potential innovation. Our first precedence was to create a smaller staff with many roles represented to find out metrics for fulfillment for the group and alignment on the undertaking facet.

Matt Hedke

Permission granted by Barton Malow

These metrics embody potential financial savings and the best way to measure them, the impact on components like security, price and schedule, and so they can fluctuate from undertaking to undertaking.

As soon as metrics are set and an thought checks the containers to maneuver ahead, it then goes to a bigger group primarily based on the issue, undertaking and proposed answer. This group consists of each undertaking and govt staff members who work collectively to pare down options earlier than initiating main analysis and transferring ahead to the demo section. If the demo section is profitable, it’s then time to formally pilot the idea.

Earlier than deploying any sources, we guarantee there’s a clear downside our innovation would resolve, get a transparent image of the target market and ensure all staff members perceive how we plan to measure success and assist the proposed answer. If one thing checks all these containers, we deploy it throughout the enterprise.

Creating effectivity via robotics

One current expertise that’s presently being piloted throughout a lot of our tasks is the usage of robotics for laser printing layouts on concrete slabs. Oftentimes, the structure space is condensed and should have some restrictions on the usage of area.

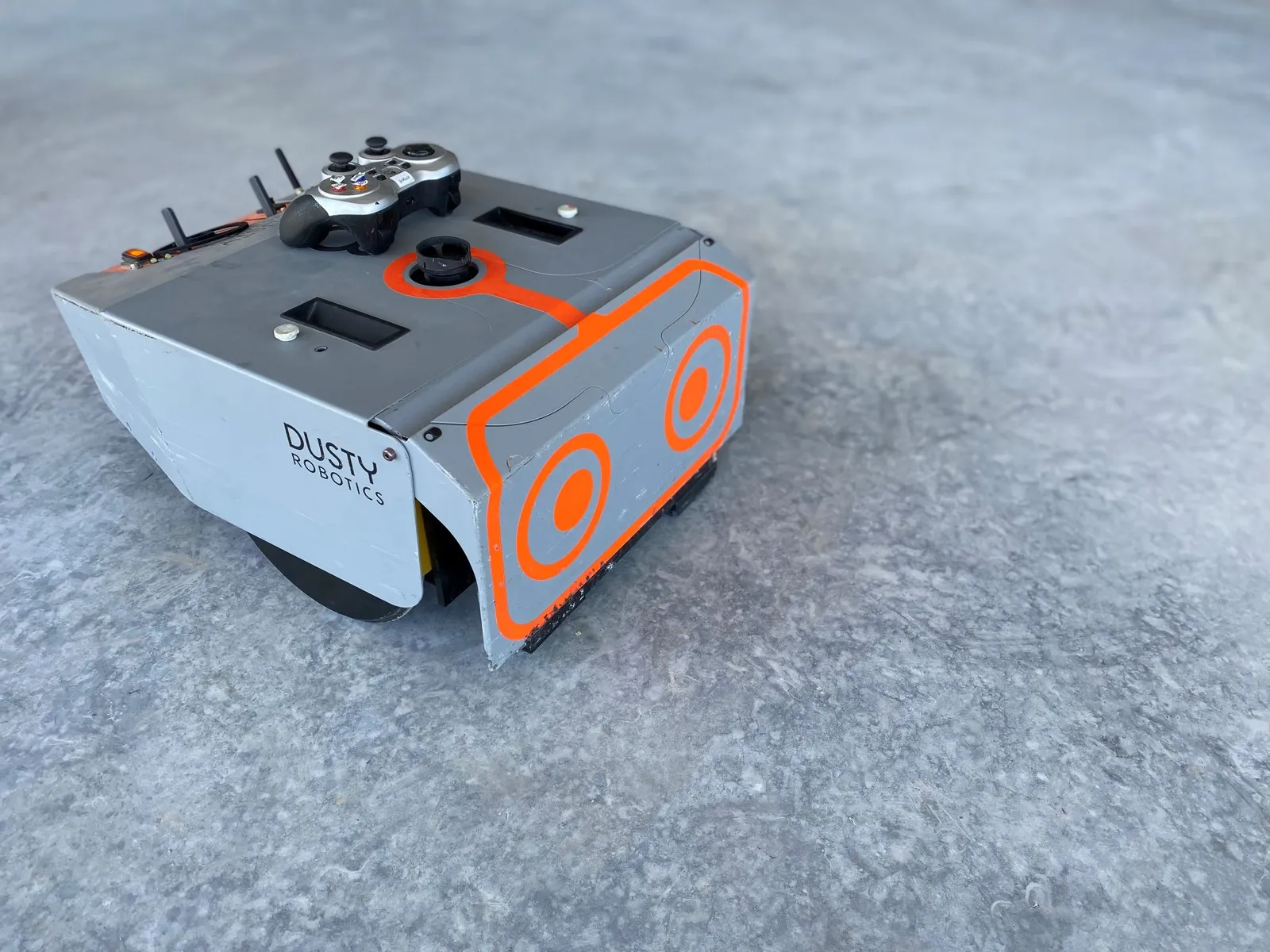

Dusty Robotics’ discipline printer is basically a laser jet printer that operates very like a Roomba, transferring across the website primarily based on inputs from the CAD file created by the VDC staff. The staff works to establish what must be laid out or printed primarily based on undertaking wants (issues like inside wall strains, laydown areas, notes and multi-trade structure as much as 1/16-inch accuracy) utilizing CAD recordsdata from the coordinated BIM mannequin to create the required paperwork.

As soon as the paperwork are reviewed and permitted, JSON recordsdata are despatched to the robotic printer, which then follows these paperwork to print linework on the ground or slab.

Dusty Robotics’ discipline printer

Permission granted by Barton Malow

Challenge groups throughout the group are using this robotics expertise and are seeing outcomes with a number of distributors and use circumstances. A few of these embody:

Pre-cast flooring structure. Tasked with constructing at floor stage, loading flooring with materials and lifting that flooring into place is a standard follow on Barton Malow’s LIFTbuild tasks. In a current undertaking, a laser-printed robotic structure allowed the association on every flooring to be accomplished, together with materials staging areas, notes and multi-trade structure instantly after flooring had been solid however previous to the fabric being loaded on the slabs for the elevate.

This was vital to total scheduling and proved to be an enormous profit not just for preplanning and multi-trade structure but additionally for enhanced security by lowering labor on website in a good space.

Inside wall structure. Leveraging laser-printed robotics for the structure of inside partitions has confirmed to be extremely productive as properly. Not solely does it velocity up the structure course of, however it additionally permits for our VDC centralized structure staff to clean the drawings for structure points previous to being on website. Because the staff is creating the JSON recordsdata for the printer, we’re collaborating with the undertaking staff on sequence, construct plan, potential points or RFI within the design forward of time so we are able to enhance the efficiencies within the file.

Utilizing robotics expertise, the JSON recordsdata had been created in two weeks, and Dusty Robotic printed 10,700 linear toes of wall line, 972 linear toes of textual content and 1,071 complete textual content objects in 45 hours of Dusty Robotic operating time, in line with Wade Tolle, centralized structure staff member. That is considerably sooner than conventional structure strategies.

Barton Malow is dedicated to persevering with to check expertise on our tasks. That features leveraging innovation to boost tasks in addition to profit our workforce.

When deployed and utilized accurately, these improvements have the added benefit of accelerating the effectivity and longevity of our individuals within the discipline. Discovering options to enhance the underside line for our shoppers is vital, however so too is maximizing future developments to assist our individuals innovate the way forward for the trade effectively, successfully and safely.