Manufacturing is a fancy course of. It requires balancing manufacturing capability, stock ranges, materials necessities and different elements to satisfy orders. When you’ve aligned these challenge elements, you must schedule your manufacturing.

Making a grasp manufacturing schedule is essential in guaranteeing your provides match demand. A sturdy grasp manufacturing schedule additionally helps your gross sales pressure and strengthens your capability to satisfy the wants of your clients.

What Is a Grasp Manufacturing Schedule?

A grasp manufacturing schedule (MPS) outlines which merchandise will probably be manufactured and when they’re made. This schedule outlines the assorted processes and assets wanted to make manufacturing transfer ahead easily whereas figuring out potential bottlenecks and creating plans to keep away from them.

A grasp manufacturing schedule is important in manufacturing, as it may be the distinction between a corporation making a revenue or experiencing a loss in income. To be sure to don’t miss something, there are a number of information sources you should use as enter for the event of a grasp manufacturing schedule. Listed here are among the mostly used ones.

- Mixture planning: This methodology permits organizations to create manufacturing plans that concentrate on uninterrupted manufacturing in durations from six to 18 months. Utilizing combination planning as enter is an effective way to create a grasp manufacturing schedule.

- Inventory stock degree: You’ll have to know your present stock ranges to create an environment friendly manufacturing schedule that minimizes stock prices down and meets buyer demand.

- Manufacturing capability: That is the utmost output that may be achieved by your group by way of manufactured items. It’s important to know this earlier than making a grasp manufacturing schedule.

- Materials necessities planning: This can be a system that’s used to calculate the parts and supplies essential to manufacture a product. The fundamental inputs embody a grasp manufacturing schedule, stock standing file and invoice of supplies.

- Gross sales forecasts: Offers estimates of future buyer demand, which is able to assist to find out how a lot product is required to be produced. With grasp manufacturing scheduling, this demand is translated into an in depth plan for manufacturing, specifying what to provide, in what portions and when. It helps corporations optimize stock ranges, scale back prices and enhance buyer satisfaction.

Get your free

Grasp Manufacturing Schedule Template

Use this free Grasp Manufacturing Schedule Template for Excel to handle your tasks higher.

Grasp Manufacturing Schedule (MPS) vs. Manufacturing Schedule

The grasp manufacturing schedule and manufacturing schedule are comparable. Nonetheless, they serve totally different however associated functions. For instance, an MPS outlines the merchandise wanted to be produced, together with the amount and when they’re wanted as decided by demand forecast and stock ranges.

This normally covers an extended timeframe, typically months forward, which offers a high-level overview of manufacturing targets. When it comes to technique, MPS helps in planning assets, managing lead occasions and aligning manufacturing with gross sales forecasts.

A manufacturing schedule, however, focuses on extra particulars and specifies precise manufacturing actions for a shorter timeframe than the MPS, normally every day or weekly duties.

It contains particular particulars corresponding to work orders, labor assignments, machine schedules and supplies wanted. That’s as a result of a manufacturing schedule is used for day-to-day operations and execution of the challenge plan outlined within the grasp manufacturing schedule.

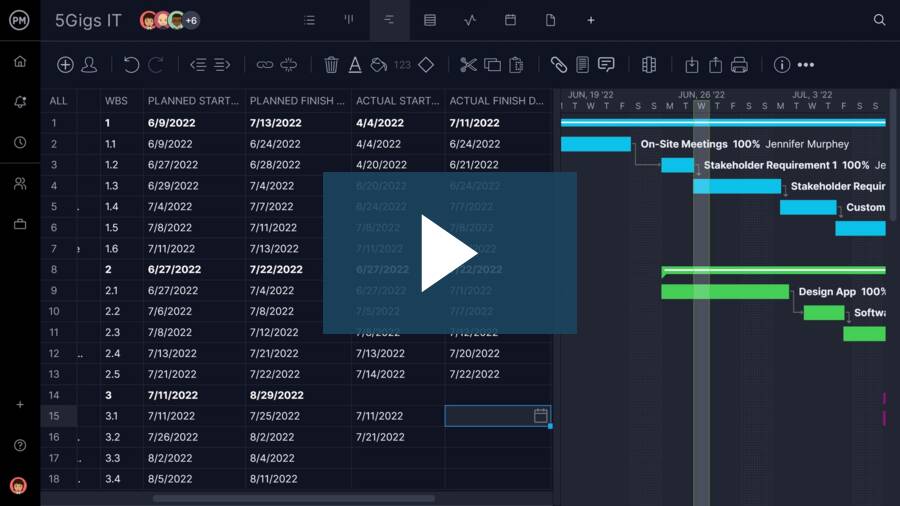

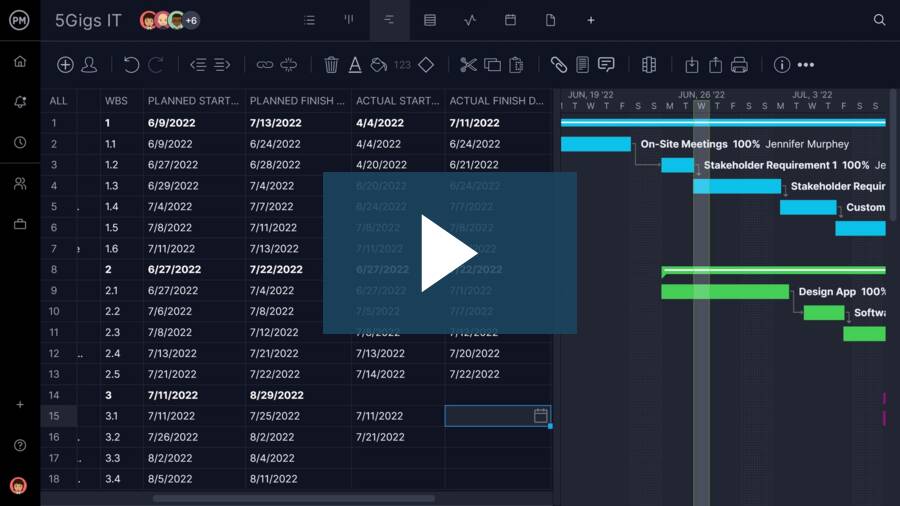

One of many best methods to make a grasp manufacturing schedule is utilizing a web based Gantt chart. ProjectManager provides an award-winning Gantt that’s versatile and collaborative to your complete crew. Schedule duties throughout the timeline, linking dependent duties to keep away from bottlenecks within the manufacturing course of. Get began with ProjectManager at this time without cost.

Why Ought to You Use a Grasp Manufacturing Schedule?

Having a plan that may forecast the demand to your product over a interval is the first objective of a grasp manufacturing schedule. Nonetheless, there are different key roles an MPS performs in manufacturing and manufacturing planning.

The primary capabilities of a grasp manufacturing schedule embody:

- Planning: Balancing market demand to supplies, labor and the capability of your tools to ship the products.

- Make changes to schedule: Schedules have to have a contingency for surprising delays or errors that cease the stream of merchandise.

- Stop stockouts: Planning for capability necessities to take care of the output of manufacturing.

- Enhance effectivity and management prices: The higher the plan, the extra seemingly you’ll keep on schedule and determine potential efficiencies.

- Facilitate order success: It does this by aligning with demand, stock administration, useful resource allocation, lead time administration and being versatile and conscious of modifications.

One other operate is to maintain your commitments to your buyer base. Manufacturing solely works when it serves its clients on time and inside funds.

When you could have the suitable grasp manufacturing schedule course of, your demand flows smoother, lead occasions enhance, communication is standardized, necessities are prioritized and manufacturing is stabilized.

Methods to Create a Grasp Manufacturing Schedule

When making a grasp manufacturing schedule, you must observe a course of to satisfy the operate of the schedule. One of the simplest ways to do this is by following these steps.

- Begin with a requirement plan, which maps the calls for that your grasp manufacturing schedule goes to reply to.

- Determine the uncooked supplies you’ll want and safe a provide chain to ship these supplies to your manufacturing.

- Develop a proposal of the grasp manufacturing schedule to verify the schedule can meet its necessities.

- Make any calculations essential to see if it could possibly meet the calls for of your grasp manufacturing schedule draft. These calculations ought to proceed all through the method to be sure to’re all the time assembly demand.

- When you’ve examined the draft and it meets your necessities, you possibly can be sure that it aligns along with your customer support, assets and the funding you’ve made into stock.

- The subsequent step is ensuring you talk the manufacturing schedule to everybody concerned within the manufacturing course of. You need to make sure that your crew is on the identical web page.

- Return to your schedule to see in case your provide is balanced with demand. It ought to let you know whether or not you must improve or lower manufacturing. This ensures you produce the orders generated by your gross sales crew and ship them on time and with the anticipated high quality.

What Ought to Be Included in a Grasp Manufacturing Schedule?

Earlier than you make your grasp manufacturing schedule, you want a requirement plan to know what your clients need. A requirement plan depends upon correct historic gross sales information, which helps you determine what demand will probably be within the coming weeks. The demand plan should be frequently reviewed and up to date.

It’s useful to have what’s referred to as a security inventory saved in case demand unexpectedly spikes. It will carry you thru the interval whilst you replace your grasp manufacturing schedule. Don’t neglect to replenish your security inventory after you employ it.

On the subject of grasp manufacturing scheduling, every firm could have its tips, however at a primary degree, a grasp manufacturing schedule will embody these elements.

- Forecasted demand: This forecast determines what merchandise should be produced, in what portions and when. This helps to make sure that manufacturing aligns with anticipated gross sales, which helps corporations meet buyer demand whereas optimizing stock ranges.

- Product checklist: An inventory of all of the merchandise you make, together with portions and the timing for every manufacturing run. This helps manufacturing align with demand forecasts and operational capabilities by offering a transparent roadmap for manufacturing.

- Manufacturing begin and finish dates: These dates assist to outline the timeline for when manufacturing ought to start and when it must be accomplished every time. This helps align with demand and handle assets extra successfully, facilitating smoother operations and well timed order success.

- Deliberate manufacturing worth: That is the variety of items you’re going to fabricate every week. Make sure to embody what number of items of every variation are made up of the full quantity.

- Precise orders: Precise orders from clients can affect the grasp manufacturing schedule and be mirrored in changes or updates to it. They supply real-time information that may result in modifications within the schedule.

- Buyer: The grasp manufacturing schedule is influenced by the shopper and their wants, market developments and precise orders. To successfully meet buyer expectations, corporations typically alter the MPS.

- Starting and ending stock ranges: The start stock represents the quantity of stock out there in the beginning of the planning interval and serves as a baseline for figuring out manufacturing wants. Ending stock is the specified stock degree on the finish of the planning interval, which helps guarantee there’s sufficient inventory to satisfy future demand with out overproducing.

- Accessible to vow items: This refers to stock out there to satisfy buyer orders after accounting for present commitments. It incorporates assessing stock ranges, managing buyer expectations and planning manufacturing.

- Security inventory: Although not usually detailed within the MPS, it’s an necessary consideration when creating that schedule. Security inventory is the additional stock saved available to mitigate dangers related to demand variability and provide chain disruptions.

- Work in progress: Not explicitly detailed within the MPS, it’s an necessary issue when planning manufacturing for scheduling manufacturing runs and managing lead occasions.

- Manufacturing prices: Once more, not normally included within the MPS, nevertheless it’s carefully tied to monetary issues when evaluating feasibility, optimizing manufacturing and reporting on prices.

- Variation sublist: You need a column with variations, corresponding to sizes or colours to doc and handle supporting techniques or processes. It may possibly affect how the MPS is developed or adjusted.

- Dates: Any schedule will need to have dates to precisely forecast demand and supply. It’s finest to interrupt your schedule into months and weeks and alter as wanted.

Grasp Manufacturing Schedule Instance

To raised perceive the MPS, let’s think about a real-world state of affairs. As illustrated within the schedule under, Acme Manufacturing is scheduling its swing shirt. 4 widgets had been created throughout this timeframe and are all in progress.

The portions vary from 500-600 items that will probably be accomplished on common in 4 days as indicated by the manufacturing begin and finish dates. The start stock degree is listed in addition to the precise orders and ending stock. There’s even a security inventory degree to deal with any fluctuations in demand or different modifications to the schedule.

The work in progress is listed in items and the manufacturing prices for every merchandise being produced are calculated on the finish of the schedule. The MPS could be up to date throughout manufacturing if needed, and that data is listed on the MPS to make sure that everyone seems to be working from essentially the most present data.

Grasp Manufacturing Schedule Template

Our free grasp manufacturing schedule template is a good instrument to get began with manufacturing planning. It may be simply personalized to suit your enterprise’s wants.

Associated: 10 Free Manufacturing Excel Templates

Advantages of Utilizing a Grasp Manufacturing Schedule

Utilizing a grasp manufacturing schedule is a necessity for manufacturing companies. The higher you perceive your manufacturing course of, the higher you possibly can meet the altering calls for of your buyer base. Listed here are among the important advantages of utilizing one.

- Helps with demand planning

- Helps with stock administration

- Helps with manufacturing staffing

- Prevents stockouts

- Facilitates upkeep planning

- Helps create higher estimates for procurement

A grasp manufacturing schedule additionally serves as a channel for communication between the gross sales and manufacturing groups. As a result of this can be a steady dialogue, the grasp manufacturing schedule is versatile and open to vary as wanted.

To summarize, it’s a plan for making no matter commodity your group produces. It schedules the manufacturing means of that commodity but in addition contains the staffing and stock which are required. The plan itself is decided by the demand for the product, and this data is offered by gross sales.

How ProjectManager Manages Your Grasp Manufacturing Schedule

ProjectManager is award-winning software program that organizes work, groups and tasks. Undertaking administration instruments may help you propose, schedule and implement manufacturing processes extra effectively.

Use our on-line Gantt chart to create a grasp manufacturing schedule that permits you to map duties throughout a timeline whereas protecting observe of prices and assets to be sure to’re by no means overspending. Even higher, the dynamic Gantt chart is versatile and could be rapidly edited to mirror modifications in orders and capability.

Gantt charts are planning instruments that show you how to schedule duties throughout a timeline. You may then hyperlink any dependent duties to keep away from bottlenecks in your manufacturing cycle. For instance, if a strap must be stitched to the physique of a purse earlier than the embroidery could be added, you determine this dependency and hyperlink the 2 duties to maintain manufacturing working easily.

See how to do this and extra by watching this brief video on find out how to schedule with ProjectManager.

The Gantt will also be shared, and since the challenge administration instrument is on-line, all information about your manufacturing course of is collected in actual time. If there’s a delay with wanted supplies, you possibly can simply alter the schedule.

The grasp manufacturing schedule must mirror demand and provide. This implies it additionally wants a instrument that may give you a high-level view of your manufacturing. The actual-time dashboard collects information and robotically calculates time, prices and different metrics to provide you a high-level view of your manufacturing.

Associated Content material

We publish blogs, movies and guides that designate all of the totally different elements of manufacturing administration. Listed here are a number of of those that concentrate on manufacturing scheduling and different comparable matters:

ProjectManager is an award-winning instrument that organizes your manufacturing that will help you work extra productively. Plan, schedule and alter your grasp manufacturing schedule in accordance with demand and capability necessities. Get began without cost.