Given their crucial impression on structural integrity, load distribution, and total security, the discourse surrounding the need of snow retention methods attracts important consideration from designers, contractors, and constructing house owners alike.

One perspective raises considerations concerning the dangers of compromising the constructing’s structural integrity resulting from snow accumulation, cautioning extreme snow might exceed the roof’s design load capability and end in catastrophic failure. Conversely, proponents of mechanical snow retention contend that these methods are important for efficient snow administration in a managed method to stop hazardous rooftop avalanches, thereby minimizing security dangers to each pedestrians and property.

So, which strategy proves to be the simplest?

Understanding the implications of every perspective is essential not solely to make sure the protection and longevity of the roof but in addition for public security. Some assist utilizing snow retention solely when crucial and encourage planning for “pure” snow shedding to keep away from extreme accumulation.

Nevertheless, this raises crucial security questions: Does “pure shedding” grow to be a security subject when a rooftop avalanche crushes a car or solely after fatalities happen? Additionally, what occurs if ice dams kind at eave overhangs, blocking “pure” snow shedding totally?

Annually, rooftop avalanches trigger intensive property injury, private harm, and even demise. That is typically resulting from makes an attempt to take away snow from a roof. The first operate of snow guards is to stop snow from sliding off the roof in an uncontrolled method, minimizing the danger of sudden avalanches. A rooftop avalanche endangers individuals and property whether or not anticipated or not.

A certifiably examined and engineered snow retention system—particular to the snow masses anticipated on the steel roof—offers a frictional interface between the roof and the snow, permitting for manageable snow evacuation by thaw and sublimation.

Forms of snow guards

Snow guards are a system of parts assembled onto a roof floor to immobilize a blanket of snow. There are two main approaches to restraining snow on a steel roof:

- Steady methods: These embrace horizontal parts, generally often called snow bars or snow fences, that are assembled laterally throughout the roof.

- Discontinuous methods: These include particular person elements often called snow stops, blocks, or cleats, typically spot-located in some sample of rows or staggered.

Each methods are usually put in at or close to the eaves and could also be repeated at intervals up towards the ridge however with higher focus close to the eave space. The suitable frequency of set up is decided by particular job circumstances and load-to-failure traits of the chosen units.

Each kinds of snow guards depend on the compressive power of the snow blanket on the interface with the snow guard units. This power is best on the base of the blanket (i.e. the portion towards the eave and instantly adjoining to the roof floor). The snow blanket is a moderately huge slab with important cohesive power inside itself. Each kinds of snow guards depend on the cohesive and shear power of the snow blanket to “bridge” between rows, or laterally from one discontinuous unit to the subsequent adjoining one.

Each kinds of snow guards have demonstrated passable efficiency when examined, engineered, and put in correctly and adequately.

Misconceptions

A typical false impression is snow guards can result in extreme snow accumulation, probably exceeding the constructing’s design structural load capability. Nevertheless, a unprecedented, uncommon climate occasion would want to happen, mixed with circumstances exceeding the protection elements constructed into the design.

The ASCE-7 appendix features a clause for “slippery roof load discount” in structural design underneath very strict circumstances. Nevertheless, many of those circumstances not adjust to different constructing codes and requirements, rendering this load discount allowance out of date. Whereas the supply was seldom used, if it had been applied, it might preclude using snow guards.

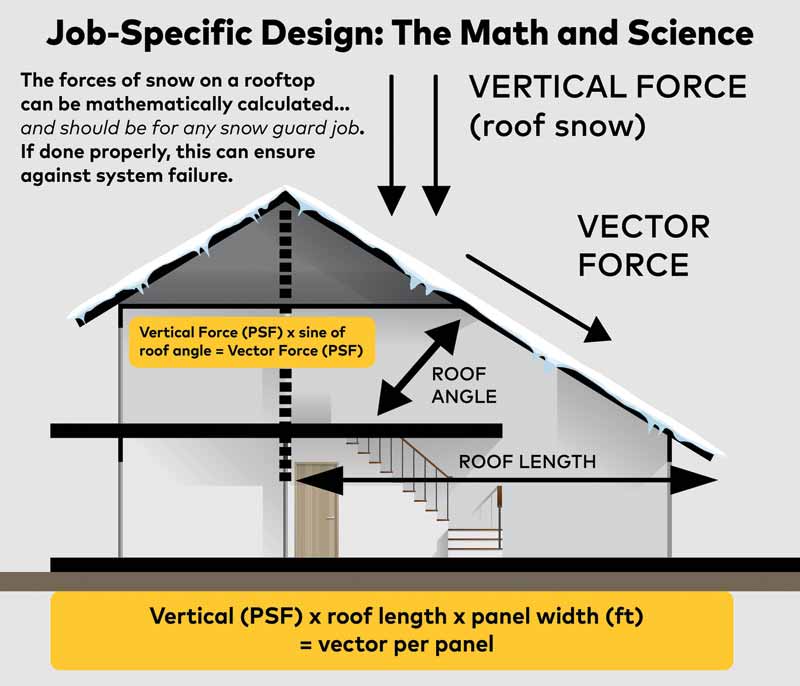

Most snow guard failures stem from under-designed methods that don’t adequately account for 3 primary design elements: design roof snow load, roof angle, and rafter size. To successfully obtain snow retention, it’s important to make use of a examined snow retention system tailor-made to those site-specific variables, together with an acceptable issue of security. Particular testing to study the failure level and cargo of the system is an crucial first step, by which the required inhabitants may be decided.

Understanding the maths and the science

Correctly calculating the required inhabitants of snow guards is crucial for any challenge. An insufficient inhabitants will fail underneath less-than-design snow masses, whereas an excessively sturdy inhabitants will end in pointless prices. The right design depends on scientific rules and math, moderately than guesswork.

The right inhabitants is discovered by calculating the tributary service masses to be resisted and matching them to the examined, allowable load resistance of the precise snow retention system proposed for the challenge.

Figuring out the vector power

The power utilized to a snow guard system is an easy calculation however varies extensively with the design roof snow load, roof slope, and rafter size from eave to ridge.

For a dependable system design, patrons ought to require proof of three high quality assurances from the snow guard vendor: licensed testing particular to the roof kind, licensed manufacturing, and proof of engineered calculations.

To retain or to not retain snow on steel roofs?

Taking the strategy of pure snow shedding to stop extreme accumulation turns into a life security subject as melting snow and ice break free from their bond to the roof, inflicting a hazardous rooftop avalanche. Subsequently, the “pure shedding” idea can solely work safely if pedestrian and car site visitors are restricted beneath the eaves of the constructing. In a sensible context, that is typically troublesome and, in some circumstances, simply not doable.

A rigorous strategy to snow retention system design, emphasizing the significance of a certifiably examined and engineered snow retention system primarily based on exact load calculations for a challenge eliminates the guesswork and considerations of system overload.

A correctly engineered mechanical snow retention system mitigates rooftop avalanches and offers efficient snow administration in a managed method, considerably decreasing the protection dangers to each pedestrians and property and leaving confidence in a system to final the lifetime of the roof. For extra info, obtain the Metallic Development Affiliation’s white papers, “Metallic Roof Design for Chilly Climates” and “Qualifying Snow Retention Programs for Metallic Roofing” at metalconstruction.org.

Rob Haddock, CEO and founding father of S-5! and director of the Metallic Roof Advisory Group, is a former contractor, award-winning roof forensics knowledgeable, writer, lecturer, and constructing envelope scientist who has labored in varied facets of steel roofing for 5 a long time. S-5! is the primary and solely snow retention producer to realize an Analysis Report of Compliance (ER) with the IAPMO EC 029–2018 business customary for testing and certifying snow retention units. For extra info go to S-5.com